Usage Areas

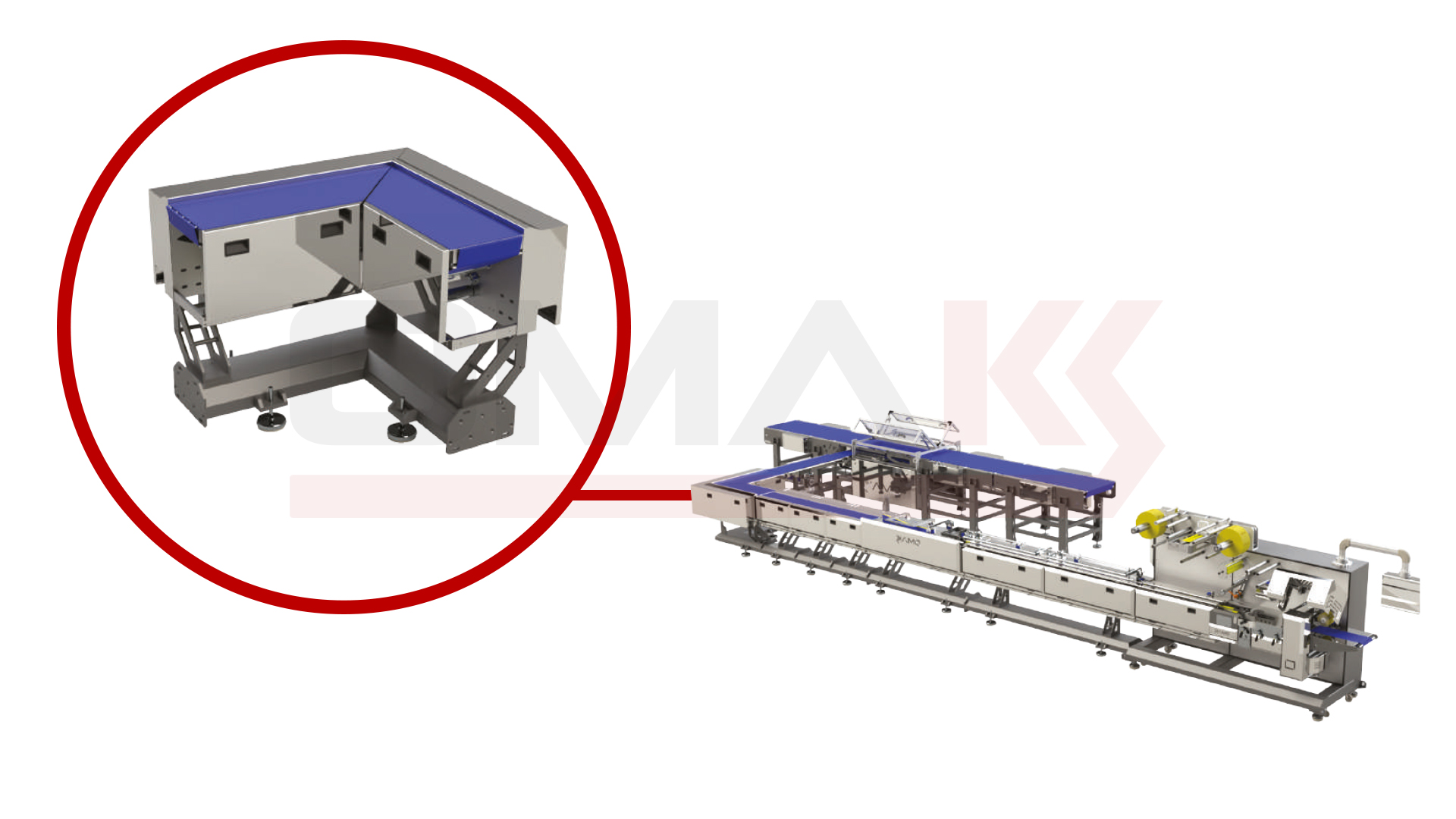

Automatic Distribution System – ADS

The Automatic Distribution System (ADS) is built in a modular structure and it is designed to direct and lead the products coming from the production line to the packaging machine after entering the system.

The system is designed for a wide range of products. With the servo motors and the asynchronous motors in the system, the system can be optimized, designed and automated according to the physical specification of the products (glueyness, softness, etc), the width of the production line, the production line placement. Up then, products would be fed to the packaging machines that is connected to the system at high speeds without interruption.

Technical Info

| Width | mm | 300-2000 |

| Electric Power | kW | 15/380/400 (+-10) |

| Air Comsumption | bar | 5,8 - 6,3 |

| Weight | kg | 1900 |

| Machine Size (LxWxH) | mm | 3800x125x1650 |

Production Process

Omaks Chocolate Packaging Machine

1

Customer Consultation

Initial contact with the customer to understand their specific needs and requirements. This phase involves detailed discussions to align the machine’s functionalities with the customer’s expectations.

2

Design and Engineering

Our engineering team develops a custom design for the machine based on the customer’s input, defining the technical specifications, materials, and overall functionality.

3

Production Planning

Detailed planning for the production process is carried out, including sourcing materials, organizing resources, and scheduling the manufacturing timeline.

4

Manufacturing and Assembly

The machine’s components are produced and assembled with strict quality control measures to ensure high performance and reliability.manufacturing timeline.

5

Delivery, Installation, and Support

The completed machine is delivered to the customer’s site, installed by our expert team, and supported with training. Ongoing after-sales support is provided to ensure optimal operation.