Usage Areas

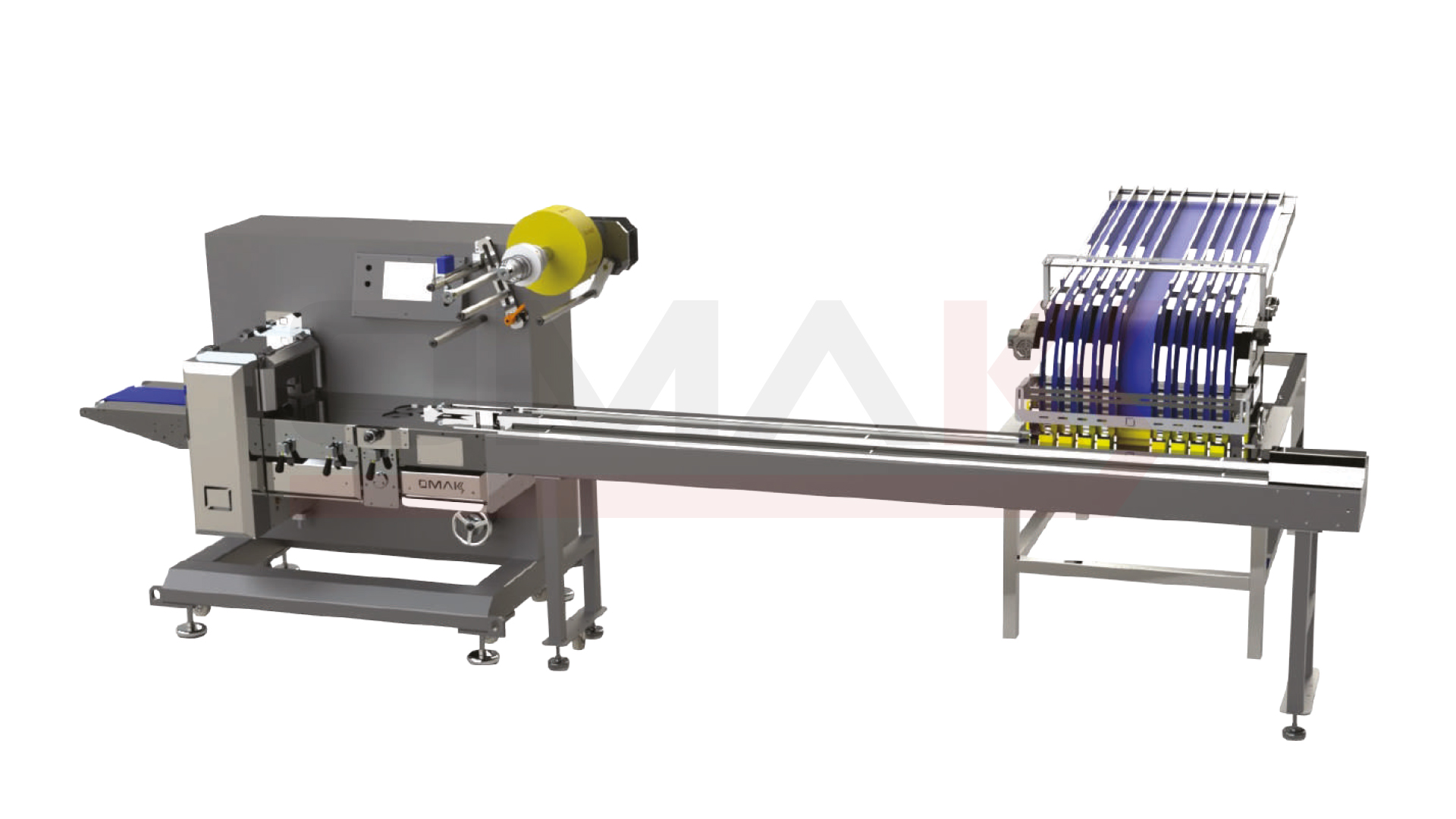

Horizontal Flow Pack Machine – EMotion - Magazine Feeding

The E-motion (Magazine Feeding) machine is specifically designed for companies with limited production lines, offering a flexible solution that adapts to various manufacturing needs, particularly for products such as biscuits and other similar products. It features customizable control options with configurations available for either 1 or full servo motors, depends on the demands of the customer, ensuring precise and efficient operation. The Magazine Feeding machine is easy to integrate into existing workflows. The intuitive touchscreen HMI enhances system management, making it user-friendly.

Magazine feeding System

| Cold Width | up to 350 |

| Coil Diameter | up to 340 |

Pusher & Feeding Conveyor

HMI Touch Screen

Disk Group

Cutting and Sealing Group

Technical Info

| Cold Seal Capacity | Pack/min | up to 120 |

| Hot Seal Capacity | Pack/min | up to 120 |

| Coil Width | mm | up to 350 |

| Coil Diameter | mm | up to 340 |

| Electric Power | kW | 3,5 kW 380/400 V 50Hz (+-10) |

| Air Comsumption | bar | 5,8 - 6,3 |

| Weight | kg | 1000 |

| Machine Size (LxWxH) | mm | 3650x2100x1600 |

Production Process

Omaks Chocolate Packaging Machine

1

Customer Consultation

Initial contact with the customer to understand their specific needs and requirements. This phase involves detailed discussions to align the machine’s functionalities with the customer’s expectations.

2

Design and Engineering

Our engineering team develops a custom design for the machine based on the customer’s input, defining the technical specifications, materials, and overall functionality.

3

Production Planning

Detailed planning for the production process is carried out, including sourcing materials, organizing resources, and scheduling the manufacturing timeline.

4

Manufacturing and Assembly

The machine’s components are produced and assembled with strict quality control measures to ensure high performance and reliability.manufacturing timeline.

5

Delivery, Installation, and Support

The completed machine is delivered to the customer’s site, installed by our expert team, and supported with training. Ongoing after-sales support is provided to ensure optimal operation.