Usage Areas

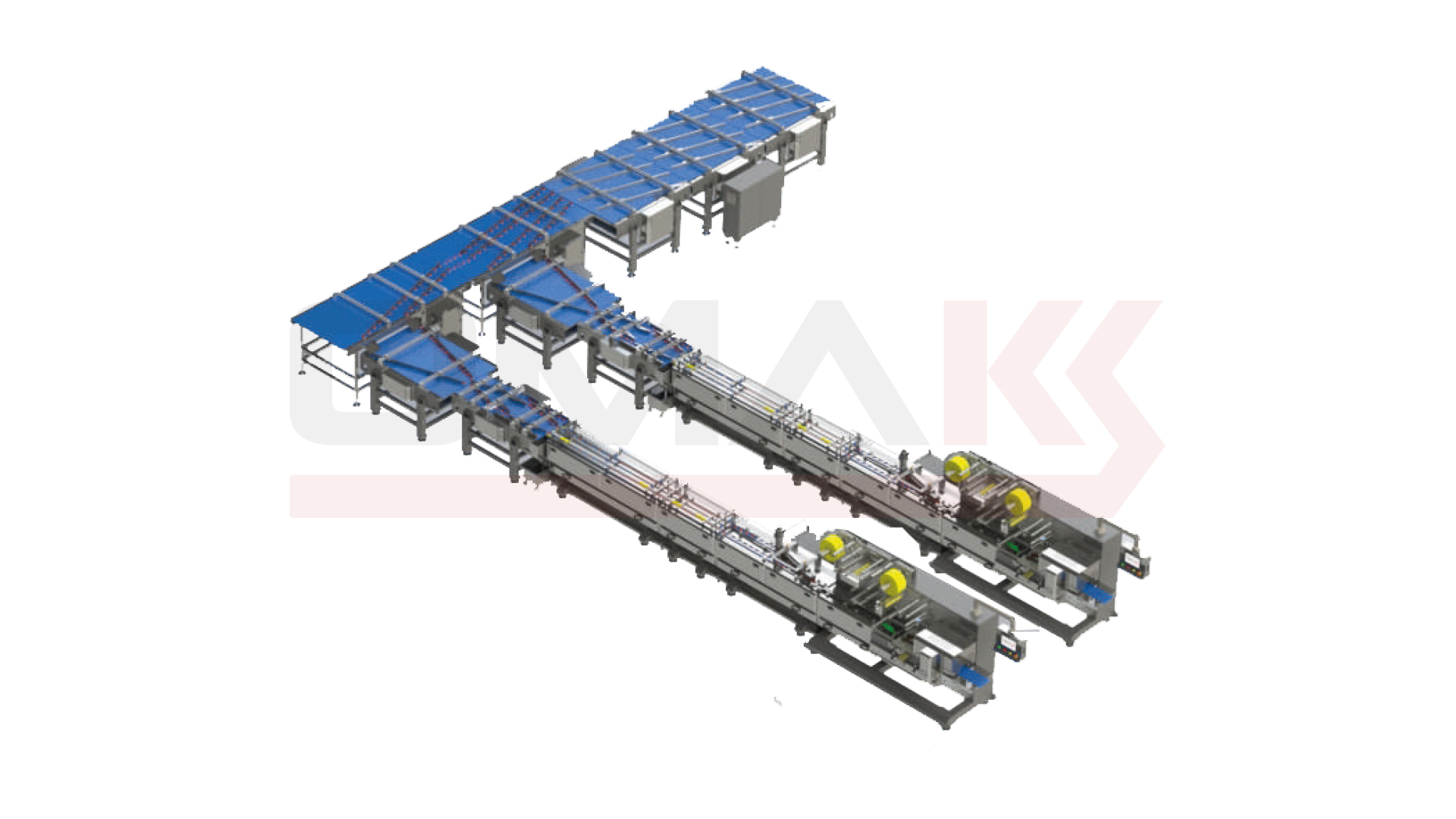

Horizontal Flow Pack Machine – Silver Pile Pack

The Twinline horizontal feeding machine is designed for high efficiency packaging. Ideal for Biscuits with a max diameter of 75 mm and a max height of 30 mm. With the servo motors and the full automated system in the machine, the machine can reach up to a capacity of 900 products per minute.

The Twinline feeding machine features customizable setting for packaging ratios, ensuring flexibility across various production needs. The machine can be easily integrated with an automatic feeding systems, enhancing efficiency while ensuring hygienic handling. The Twinline model simplifies operation, resulting in significant time and cost saving.

| Cold Seal Capacity | up to 700 |

| Hot Seal Capacity | up to 200 |

| Cold Seal Capacity | up to 700 |

| Hot Seal Capacity | up to 200 |

Technical Info

| Capacity 2x2 | Pack/min | 180-220 |

| Capacity 2x3 | Pack/min | 150-180 |

| Coil Width | mm | up to 300 |

| Coil Diameter | mm | up to 400 |

| Electric Power | kW | 15/380/400 (+-10) |

| Air Comsumption | bar | 5,8 - 6,3 |

| Weight | kg | 3700 |

| Machine Size (LxWxH) | mm | 3800x125x1650 |

Production Process

Omaks Chocolate Packaging Machine

1

Customer Consultation

Initial contact with the customer to understand their specific needs and requirements. This phase involves detailed discussions to align the machine’s functionalities with the customer’s expectations.

2

Design and Engineering

Our engineering team develops a custom design for the machine based on the customer’s input, defining the technical specifications, materials, and overall functionality.

3

Production Planning

Detailed planning for the production process is carried out, including sourcing materials, organizing resources, and scheduling the manufacturing timeline.

4

Manufacturing and Assembly

The machine’s components are produced and assembled with strict quality control measures to ensure high performance and reliability.manufacturing timeline.

5

Delivery, Installation, and Support

The completed machine is delivered to the customer’s site, installed by our expert team, and supported with training. Ongoing after-sales support is provided to ensure optimal operation.